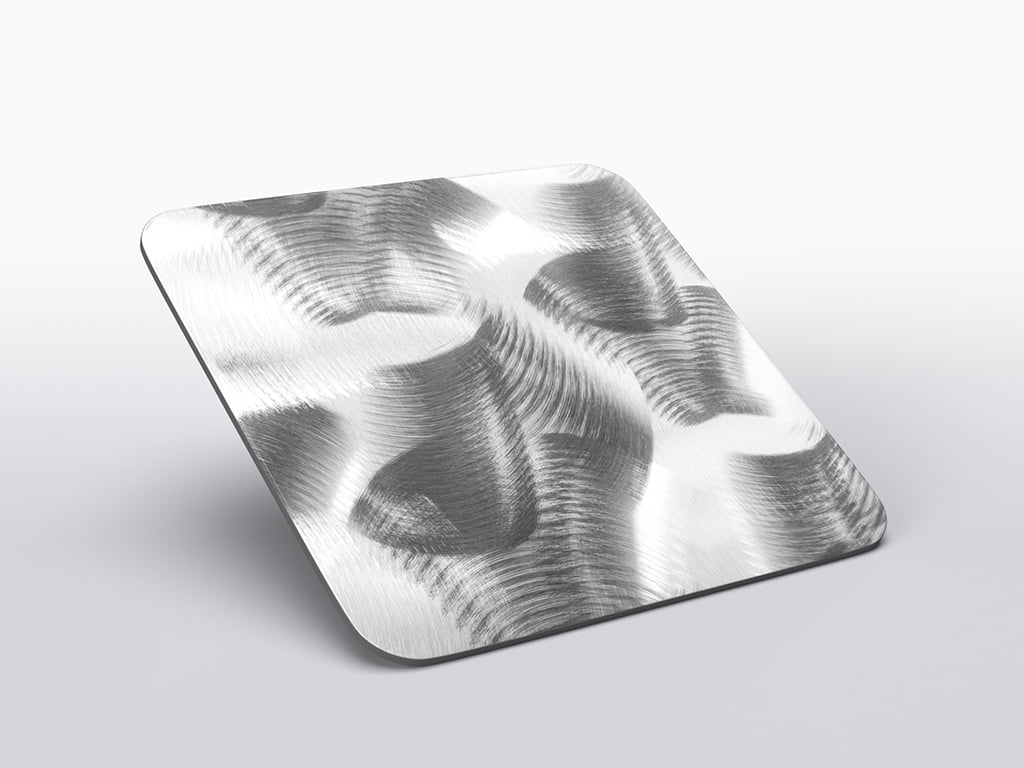

Random Swirl

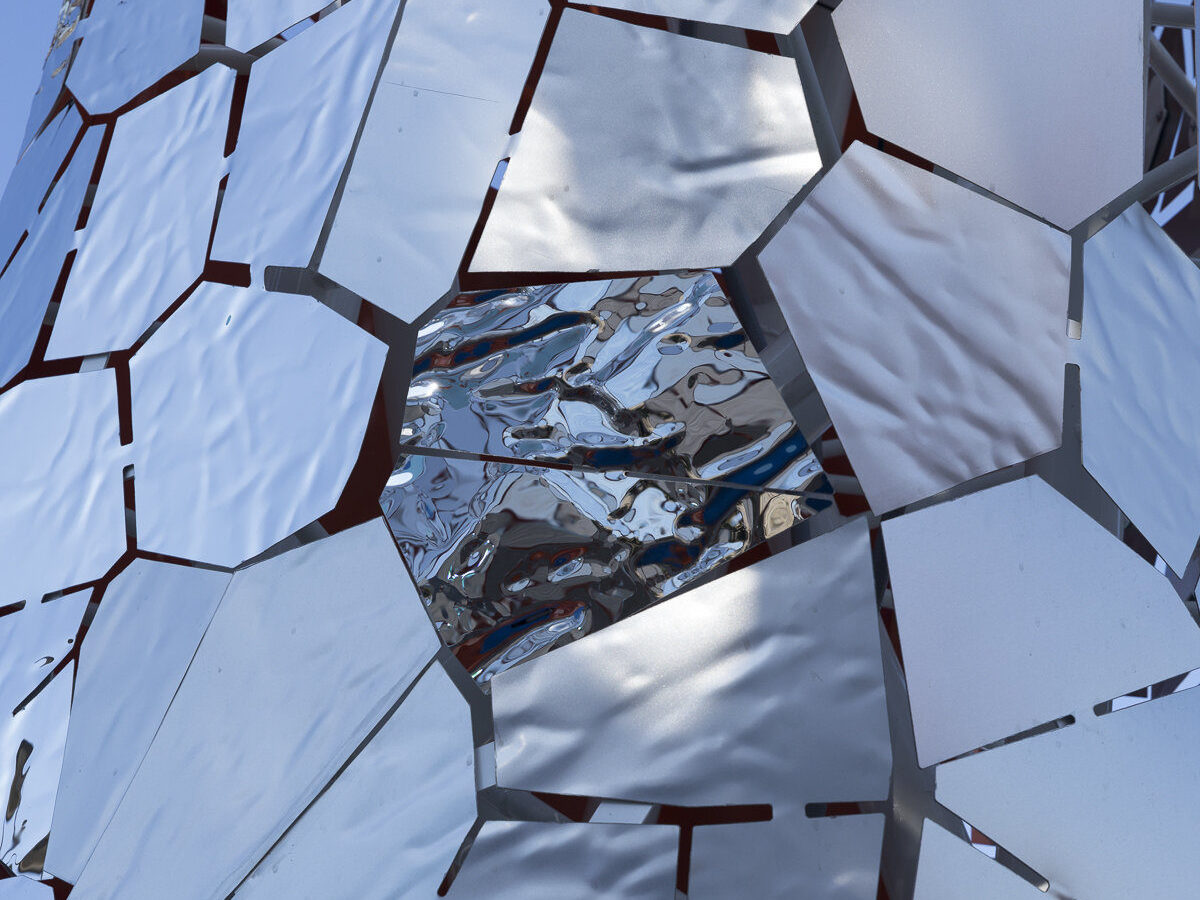

Random Swirl is a decorative steel consisting of a patterned polished finish applied mechanically to the surface of stainless steel sheets. These decorative steel finishes can be created with various visual effects. They are designed for architectural applications such as wall panels, elevator cabs, coping, and trim.

304, 304L, 316L, 430

Plate – 26ga

36, 48, 60″ wide. Standard 96, 120, 144 lengths. Custom sizes available!

Novacel 4228REF Fiber Laser PVC standard. Other PVC and paper interleaf options available on custom orders.

Contact us for more information about this product.