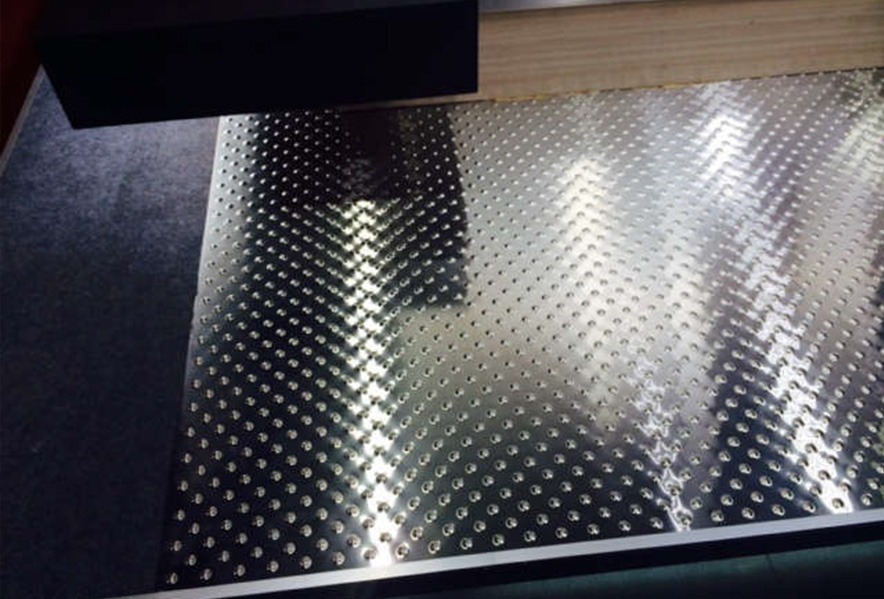

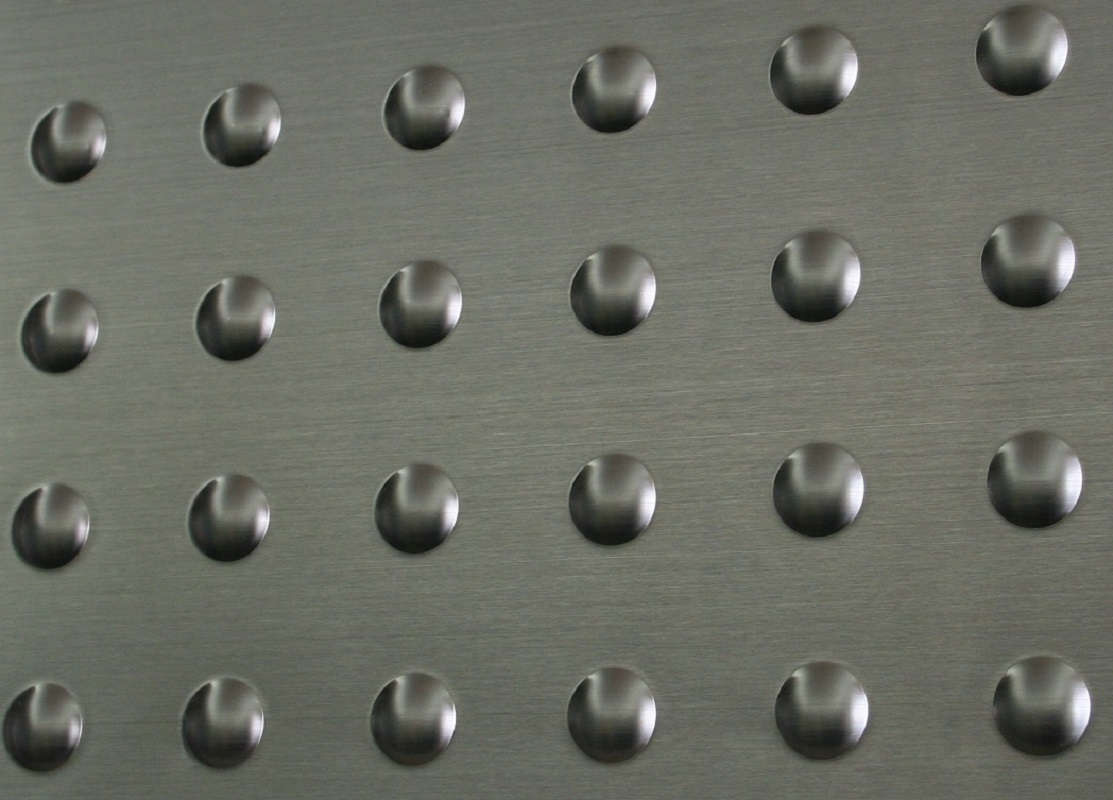

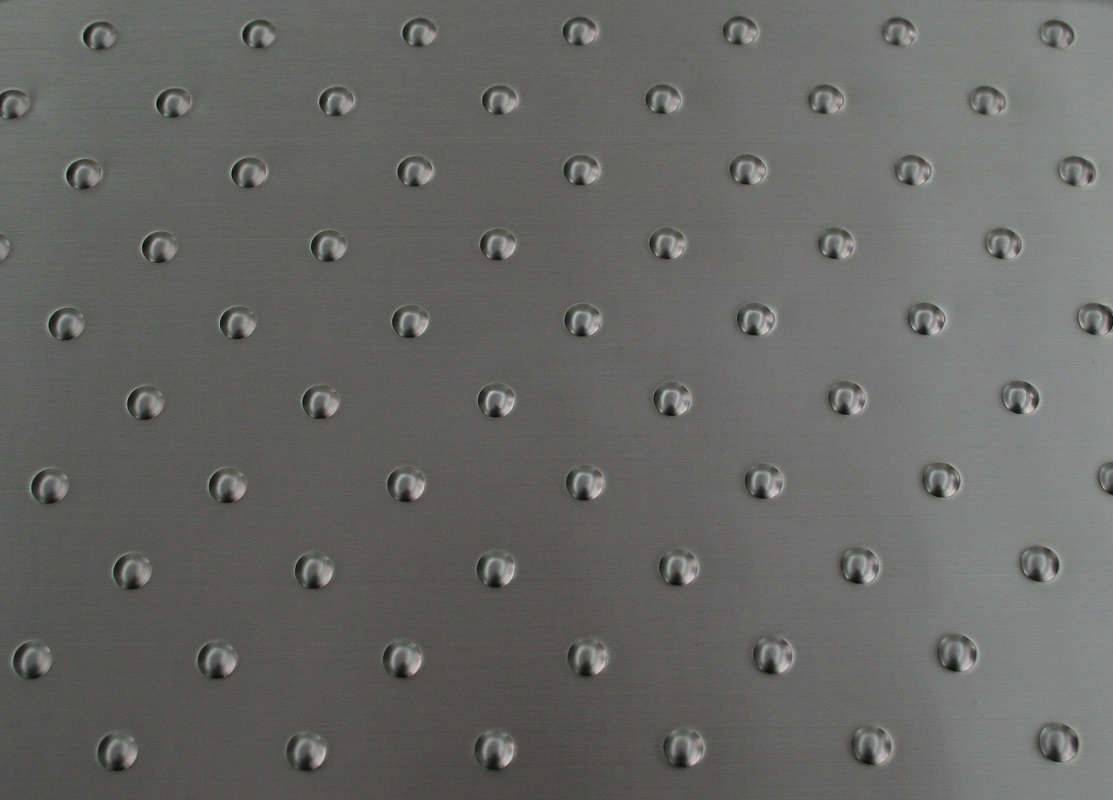

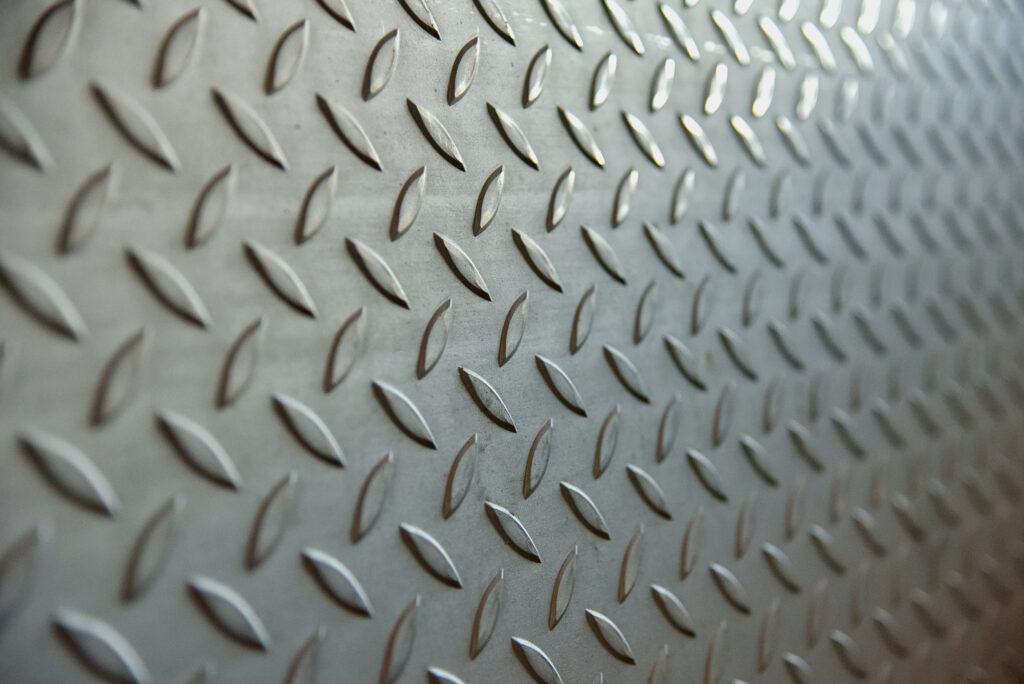

Diamond tread plate—also known as diamond plate, tread plate, tread brite, floor plate, deck plate, or checker plate—is a uniquely textured metal product widely recognized for both its practical and aesthetic value. Characterized by a raised diamond-shaped pattern, this finish enhances traction and durability, making it a material of choice across numerous demanding environments.

Diamond Tread Plate Key Applications

The primary appeal of diamond tread plate lies in its slip resistance. This quality makes it a go-to material for surfaces where safety is paramount, including:

- Industrial and commercial settings: Steps, ladders, ramps, floors, and catwalks in warehouses and factories.

- Vehicle fabrication: Tailgates, running boards, and interiors of emergency vehicles, fire trucks, semi trucks, food trucks, utility vehicles, and trailers.

- Loading & unloading zones: Loading docks and platforms where foot traffic and wheeled equipment require dependable traction.

Hygienic and Corrosion Resistance of Diamond Tread Plate

Beyond its rugged durability, diamond tread plate is highly valued for its anti-corrosive properties. This makes it ideal for environments requiring frequent cleaning or exposure to moisture and chemicals. In sectors such as:

- Food processing

- Commercial kitchens

- Sanitation areas

…it’s common to see tread plate used on walls, floors, and structural elements for both cleanliness and protection.

Protective Capabilities of Diamond Tread Plate

The raised diamond pattern also adds a layer of impact resistance, making tread plate a smart choice for guarding vulnerable surfaces. It’s widely used as:

- Corner guards

- Door protection

- Truck bed liners

- Tailgate shields

Material Options for Diamond Tread Plate

Despite “plate” being in the name, this finish comes in a wide range of thicknesses to accommodate light to heavy-duty applications. It is most commonly manufactured in:

- Aluminum (3003 & 6061) – lightweight and corrosion-resistant

- Carbon steel – strong and cost-effective

- Stainless steel (304 & 316L) – highly durable and resistant to corrosion and chemical exposure

Diamond Tread Plate Design & Finish Variability

Diamond tread plate isn’t just utilitarian—it can also be a visual statement. Customers can choose from a variety of patterns and finishes to meet specific functional or aesthetic needs:

- Brite Finish – shiny and reflective for high visibility

- Mill Finish – raw and rugged

- Brushed Finish – refined with a linear texture

- Mirror Finish – highly polished, decorative appearance

Why Choose Diamond Tread Plate from Mirror Metals

Mirror Metals has a 25-year history as the premier stainless steel distributor.

Diamond tread plate’s combination of safety, durability, corrosion resistance, and design flexibility makes it a material staple in industries ranging from transportation and manufacturing to food service and public safety.

Whether for functional flooring, hygienic wall cladding, or protective vehicle outfitting, this versatile metal is a high-performance solution across countless applications.

Reach out with any questions, we can quote a custom project for you! Our quilted stainless steel is designed for the realities of the road—harsh weather, road debris, and frequent cleaning.